Video Resources

A collection of online videos that go in depth on particular topics. Contact me if you have any questions!

Featured Video

High Performance Building Assemblies Course Intro Peter Yost

Video Series: Roof Vent Testing

Wingnut Roof Vent Testing: Round 3 #1: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #2: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #3: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #4: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #5: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #6: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #7: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #8: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #9: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #10: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #11: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #12: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #13: Brattleboro VT September 2019

Wingnut Roof Vent Testing: Round 3 #14: Brattleboro VT September 2019

Video Series: Roof Vent Testing

Wingnut Testing: 208 Fairview Kitchen exhaust vent – all interior doors to kitchen closed

Wingnut Testing kitchen exhaust, Leonard Farm, high speed with grille filters removed.

Wingnut Testing kitchen exhaust, Leonard Farm, high speed with back door cracked open.

Wingnut Testing kitchen exhaust, Leonard Farm, high speed

Wingnut Testing kitchen exhaust, Leonard Farm, medium speed.

Wingnut Testing kitchen exhaust, Leonard Farm, low speed

Wingnut Testing kitchen exhaust, 208 Fairview St, 150 cfm kitchen exhaust, interior doors open

The pressure vessel driven by a mattress air pump alternately pressurizes and depressurizes to simulate how bellowing stress PSA tapes spanning the wall sheathing to the window flange in rough open…

Wingnut Roof Ridge Vent Testing: 10:12 pitch, 1-inch vent space, non-vertical-leg baffle type ridge vent, wind driving force using duct blaster.

Wingnut Roof Ridge Vent Testing: 10:12 pitch, 1-inch vent space, vertical-leg baffle type ridge vent, wind driving force using 750 duct blaster.

Wingnut Roof Ridge Vent Testing: 10:12 pitch, 1-inch vent space, non-vertical-leg baffle type ridge vent, stack effect driving force using 750 watts of IR lamps.

Wingnut Roof Ridge Vent Testing: 10:12 pitch, 1-inch vent space, vertical-leg baffle type ridge vent, stack effect driving force using 750 watts of IR lamps.

Wingnut Roof Ridge Vent Testing: 3:12 pitch, 1-inch vent space, vertical-leg baffle type ridge vent, wind driving force using duct blaster.

Building-Wright.com WIngnut Ridge vent testing – vent #3, 12:12 pitch, 1-inch vent space

Building-wright.com Wingnut Ridge Vent Testing #1, 12:12 pitch, 1-inch vent space

Building-wright.com blog: Wingnut Testing: Soffit-to-Ridge Roof Venting – Basement video of ridge vent 2, 3:12 pitch

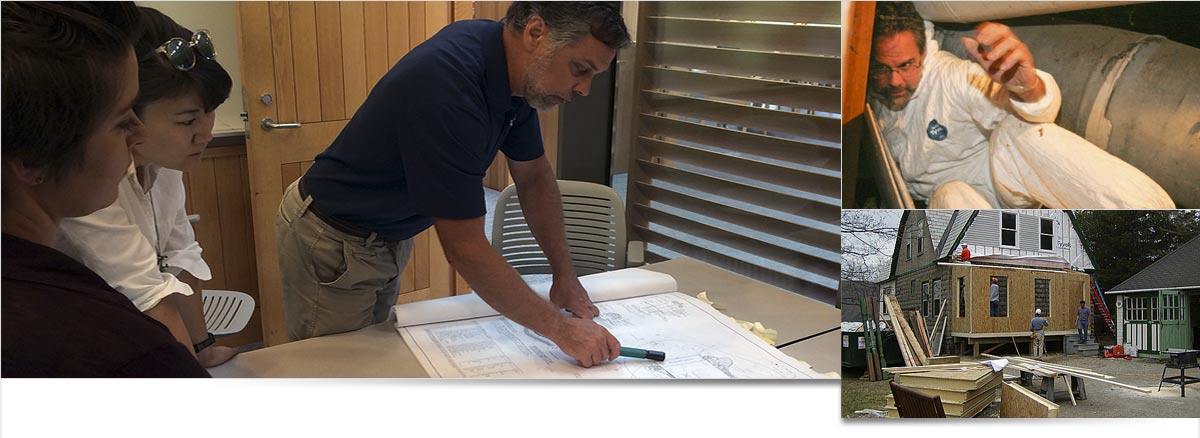

Beauty goes more than skin-deep for high performance buildings. I work with architects and builders to achieve designs and materials that result in buildings tuned to their climate and site, successfully managing the elements for durable enclosures, comfortable and safe interiors.

Getting new buildings to work right is easy compared to understanding and then changing existing buildings, especially ones you know are not working right. I have a system for assessing old buildings, then using building science to make sure that what we do to them makes them work better, not worse.

Since completing my Master’s Thesis in 1993, a big part of my life has been technical writing related to building performance. From blogs to investigation summaries, from building product installation manuals to multi-year government project reports, I have honed my writing to be clear, concise, accurate.

I have developed curriculum for and taught building performance to high school trade students, graduate students in architecture and environmental management, and every type of building professionals you can imagine: engineers, architects, construction managers, code officials, trade contractors, and even a few bankers along the way. I tailor my materials to the length of the course and keep engagement high no matter who the participants are.

Most testing done in the building industry is done in labs under carefully prescribed and controlled environments, having NOTHING to do with what takes place in the real world. I work with building industry professionals and product manufacturers to develop field service life prediction testing under jobsite conditions. It’s testing where the rubber hits the road.