Compressible gaskets keep air and water barriers continuous without liquid sealants or adhesive tapes. But they don’t all last equally well.

In the U.S., we tend to put a lot of faith in caulks, tapes, and wet-applied sealants. But in Europe it’s a different story.

Some Gaskets can be used in place of tapes or liquid sealants, mainly as part of residential air barrier systems. According to Lee Jaslow of Conservation Technologies, a leading U.S. distributor of high-performance gaskets, the market for gaskets in residential construction is small but growing, with increased interest due to high-performance rating systems such as Passive House.

Photo: Hammer & Hand

Memory is everything

Structurally, there are two types: air-filled bulb and cellular foam gaskets. The former are usually referred to as weatherstripping; despite the many different profiles, the fin and the air bulb distinguish these types of gaskets.

Cellular foam gaskets have tiny gas pockets throughout; these gaskets can be made from a variety of substances: PVC, Neoprene (polychloroprene), EPDM (ethylene propylene diene monomer), Santoprene (an Exxon Mobil proprietary cross between EPDM and polypropylene), and new-to-the-market silicone.

The key to all gaskets is compression and memory; gaskets must maintain their flexibility through different levels of compressive loading over time to keep water and air in or out. In general, there is a fairly strong relationship among these characteristics of gaskets: cost, durability, and load.

- PVC gaskets are the least expensive and least durable and cannot be used with heavy loads, such as structural loading between floor and bottom plates.

- Neoprene gaskets represent a mid-level cost/durability/load option.

- EPDM and Santoprene are considered premium gaskets that are appropriate for structural loading, maintaining their memory over long periods of time.

- Cellular foam extruded silicone gaskets are relatively new to the construction market and represent another premium gasket option.

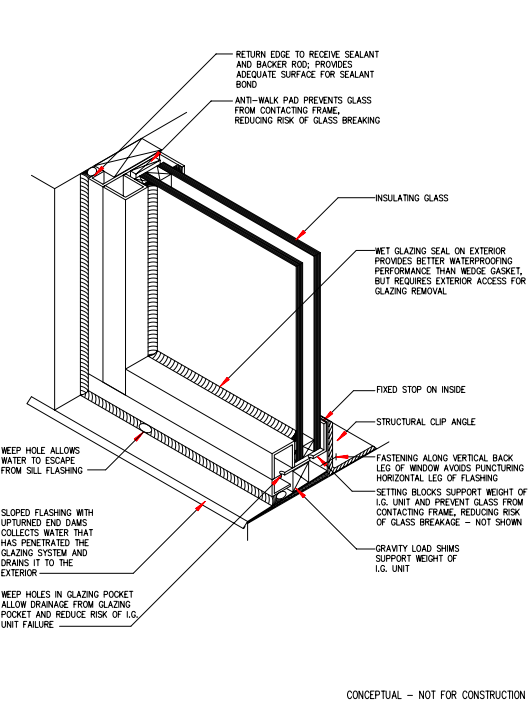

Wet versus dry glazing

In commercial building, gaskets have a special application in one of two methods to set glazing.

“Wet glazing” is setting the exterior glazing using structural liquid sealants in a face-sealed system. The continuous beads of sealant are designed and installed to keep water out of the glazing set and system.

In a “dry glazing” set, gaskets accomplish the structural glazing set and are designed with drainage channels to move water off and out of the glazing installation.

Sneh Kumar is the Manager of Department of Energy Projects for Traco – Alcoa Building and Constructions Systems, working on high-performance curtainwall systems. “We use both dry and wet glazing systems, depending on the economics of the project and the manufacturer of the glazing,” says Kumar. “Same with the types of gaskets; the economics of the project and specific profiles of the glazing manufacturer drive this decision. I can tell you that both systems are very dependent on craftsmanship and quality control, one of the reasons we prefer systems for which the glazing set is a plant rather than a site operation.”

Source: NIST

But what about service life?

It seems to boil down to experience.

When I asked both Jaslow and Kumar how they evaluate the service life of gaskets, they emphasized experience over specific studies or standardized tests, mainly because there simply aren’t any for how long various gaskets last in the field.

“We know that gaskets have been a key part of airtight homes in European countries such as Sweden for nearly 40 years,” says Jaslow.

Kumar says Traco uses a battery of ASTM tests and AAMA standards to gauge durability, but “it all comes down to experience at Traco; we know the products and systems that have performed for us over the last 20 or so years.”

So…sealants, tapes, or gaskets?

We know that each material can give initial continuity to our air and water barriers.

What we still don’t know is which systems and specific types of products sustain their performance over time. We are moving toward predictive, standardized tests of field service life for liquid sealants. And efforts such as the Tremco Sustainable Building Solutions Test Facilityrepresent a huge step forward.

But for the time being, keep your craftsmanship and quality control high, don’t skimp on spending for something just because it’s buried in the wall (skimp on the stuff that’s easier to replace, if you must!) and gather your own performance experience over time.