Is ThermalBuck a face-sealed or a water-managed window installation system — or a little of both?

ThermalBuck inventor John Brooks is a very clever, passionate building professional who is job-site savvy. He saw a weak component of high-performance walls: wood window bucks in exterior walls with exterior rigid insulation. His ThermalBuck system virtually eliminates that thermal bridge and is very airtight to boot.

ThermalBuck is a “Rough Opening Extension Support Element” with a high-density EPS core and a high-density plastic casing (a lot like a truck bed liner). It is structurally fastened to the wall framing using nails and adhesive, and then the window is structurally fastened through ThermalBuck to the framing, using long #10 screws. GBA news editor Scott Gibson reported on ThermalBuck in an April 2016 article called “An Alternative to Wood Window Bucks.”

ThermalBuck is quite newsworthy

The novelty of ThermalBuck and the tirelessness of John Brooks have led to ThermalBuck getting quite a bit of attention as a high-performance “outie” flanged window installation system.

- At Greenbuild 2015, my former company, BuildingGreen, called out ThermalBuck in an article, “Greenest of the Green Energy-Saving Products from Greenbuild.”

- The ever-popular Matt Risinger did a “Risinger Goes Rogue” video on the ThermalBuck in November 2016.

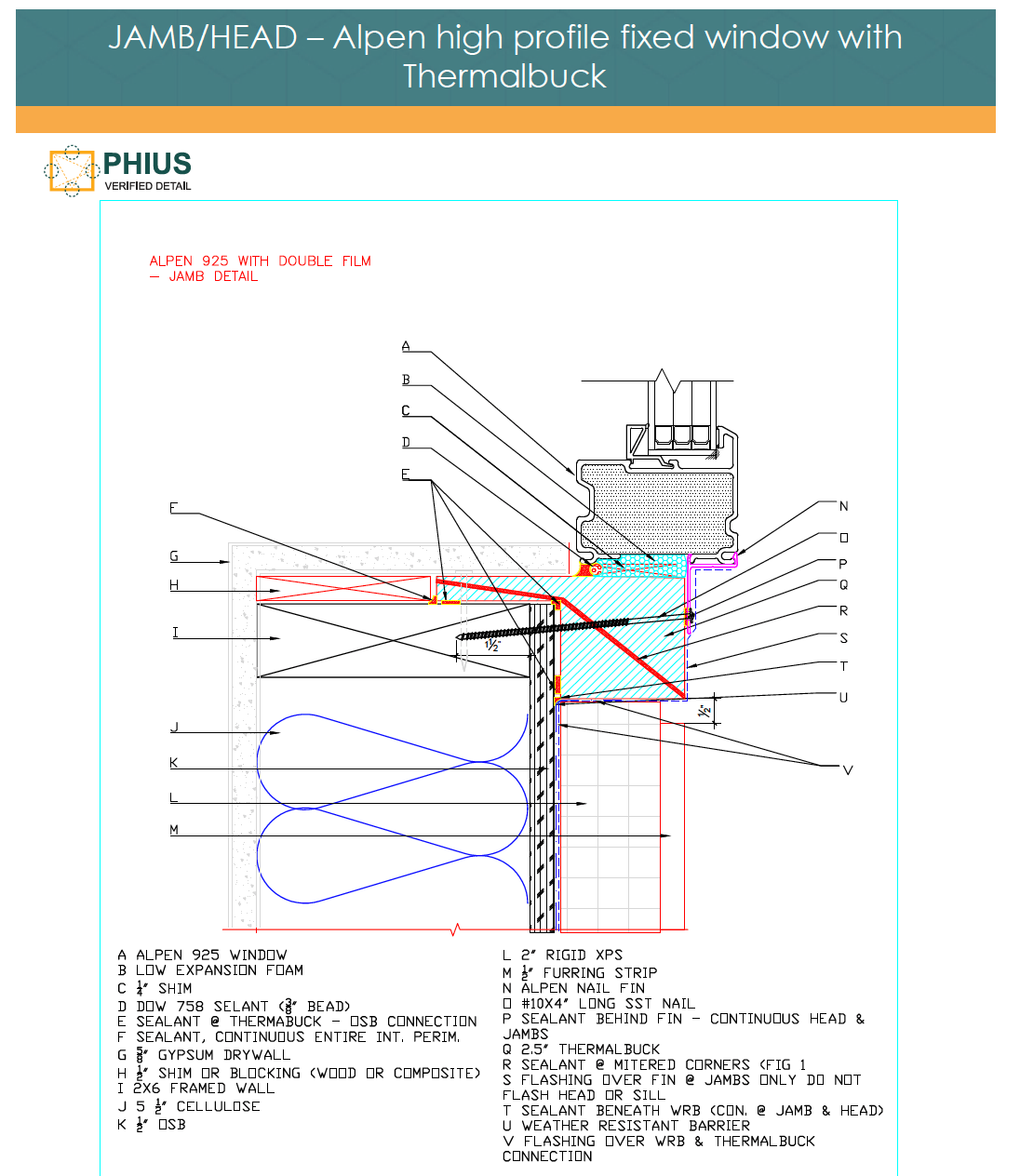

- Passive House Institute U.S. (PHIUS) identified ThermalBuck as a “verified” window installation detail (with Alpen Window).

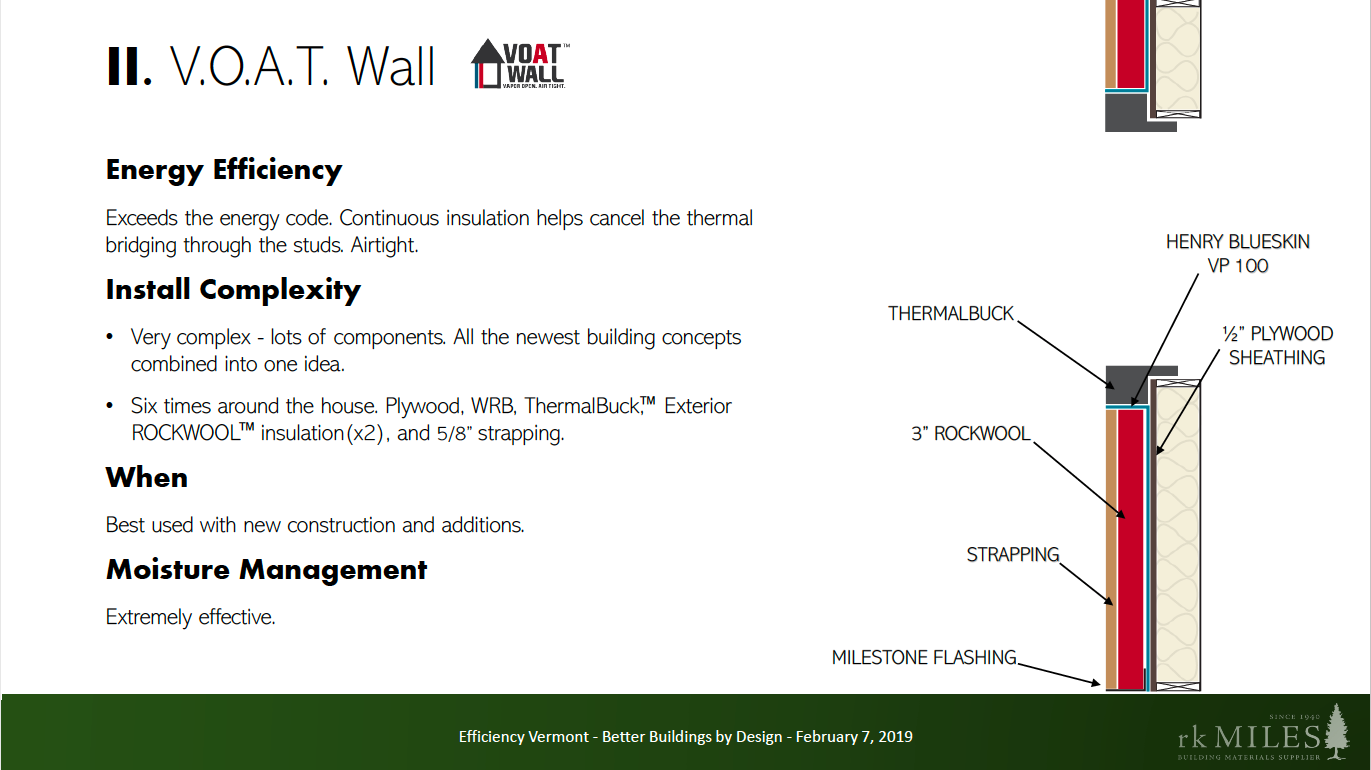

- R.K. Miles, a building materials supplier in Vermont and Massachusetts, identifies ThermalBuck as a “featured product” and a key component of a wall system that it calls the vapor-open air-tight (VOAT) wall.

- An R.K. Miles employee named Rick Stone gave a presentation on vapor-open wall systems, mentioning ThermalBuck in the presentation.

Nick Stone’s presentation was at the Better Buildings By Design conference in Burlington, Vermont. At that conference, I saw Stone compare five wall assemblies. The comparison was based on 4 key elements, including moisture management. Nick’s presentation identified the VOAT wall as having “extremely effective moisture management.”

But when I looked at the five wall mock-ups in the front of the conference room, I saw just one — the ThermalBuck VOAT wall — that did not accommodate a sloped sill or a back-dammed sill pan.

It sure looked like the ThermalBuck system resulted in a face-sealed rather than a water-managed window installation. But ThermalBuck claims to have an “integrated sloped sill.” So which is it?

Face-sealed vs. water-managed window installations

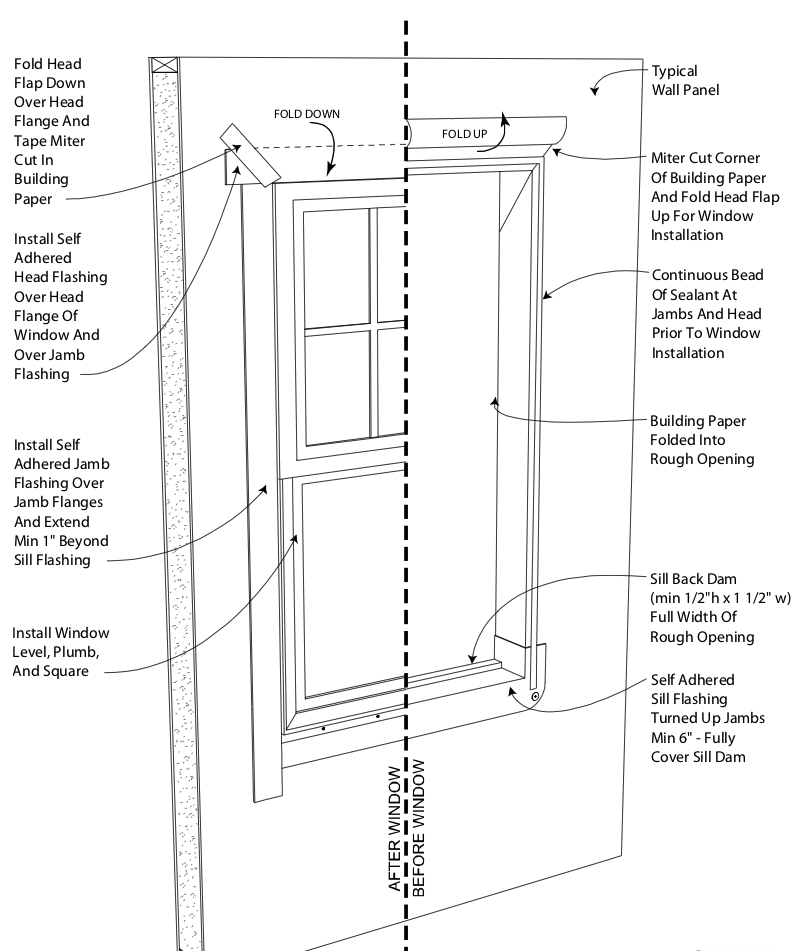

GBA’s Detail Library has a series of details for “face-sealed” and “water-managed” window installations. The key difference between the two is that the former relies on keeping water out with sealant at the face of the water-resistive barrier (WRB) while the latter adds a weather-lapped rough opening system leading to a sill pan that drains to the exterior.

The Building Science Corporation climate-based Guides and their Water Management Guide state that while water-managed window installations are recommended for all levels of bulk water exposure, situations exist that will tolerate a face-sealed approach: regions with less than 20 inches of precipitation, sheltered designs, storage/reservoir claddings, and high drying potential wall assemblies. While not explicitly stated that all of these conditions are required for a face-sealed window installation, I believe that the full monty is implied.

Details of the ThermalBuck window installation system

ThermalBuck has several step-by-step installation guides available on their website as well as several installation videos.

I believe that all of ThermalBuck’s installation methods have the following characteristics in common:

- Reliance on sealant as an adhesive: Continuous beads of sealant are used as an adhesive on the interior of horizontal and vertical legs. This includes the horizontal and vertical legs of the sill component. The mitered cut joints of all four of the “picture-framed” pieces of ThemalBuck are beaded with sealant just prior to installation.

- Reliance on sealant as a face-seal: Continuous beads of sealant as fillet joints are run on both the interior and the exterior of all ThermalBuck components.

- High-performance silicone sealants (DAP Dynoflex 800 or Dow Corning 758) are recommended throughout the sealant system, but ThermalBuck does not require their use.

- The 1/16-inch cant built into every length of ThermalBuck results in a slight down-and-out slope to the sill or horizontal leg. John Brooks refers to this slope as an “integrated sill pan for drainage.”Authors’ Note, 4-30-19: From the ThermalBuck manufacturer – The very first TB version had a sill slope of 1/32-inch but 2 – 3 years back, TB re-configured the slope to 1/16-inch.

- Windows installed with the ThermalBuck system must be flanged. (While this is not stated by ThermalBuck, I could not find any examples showing unflanged windows, nor do I think the system is designed for unflanged windows).

- ThermalBuck window installations are all outie installations; any sheltering to reduce the window’s exposure to bulk water would need to come from design elements (eave overhangs, window roofs or window overhangs, etc.).

- Weather-lapped tape flashings are installed to cover the face of the vertical legs of the ThermalBuck components after the flanged window is installed.

So what is the problem?

Everything is weatherlapped and there are two systems keeping water out: the face sealant of the ThermalBuck installation and the tapes that are used when the window is installed. The problem is, as John Brooks states in one of his installation videos (“How to Install ThermalBuck – Exterior Insulation as the WRB” ), “All windows are eventually going to leak; it’s just a fact of life.”

If the window unit leaks to the interior of the window unit (and interior to the interior fillet joint of sealant), that water has no place to go but in. And if any part of the WRB/window flashing system fails and water makes its way in rather than out at the rough opening, that water has no place to go but in.

High performance exterior wall assemblies all have these four control layers in order of priority:

- Bulk water

- Air

- Vapor

- Thermal

ThermalBuck rocks 2 and 4, and in the VOAT wall does the same for 3. But the most important first one — bulk water — the control layer is not up to the same level of defense as the other three control layers, in my opinion.

Can ThermalBuck rock number 1?

What if:

- Before the ThermalBuck system is installed, the rough opening is flashed and a sill pan with a backdam or sloped sill (or both) is installed, and

- When the ThermalBuck sill leg is installed, it is not sealed with adhesive on its horizontal and vertical leg (so that any leaked water directed by the sill pan could weep out of the ThermalBuck sill leg)?

Would that do it? Make ThermalBuck high-performance all the way around? I am sure there are additional details to consider and issues that these changes will raise, but as we strive to improve the performance of buildings, we need to honor, by priority, those pesky control layers.